The principle of catalytic ozone oxidation technology for wastewater treatment is to use strong oxidation of ozone under the action of the catalyst

active center to destroy the original structure of refractory organic molecules and transform them into material molecules that are conducive to

biochemical degradation. This leads to degradation and digestion, which can effectively reduce the level of pollution.

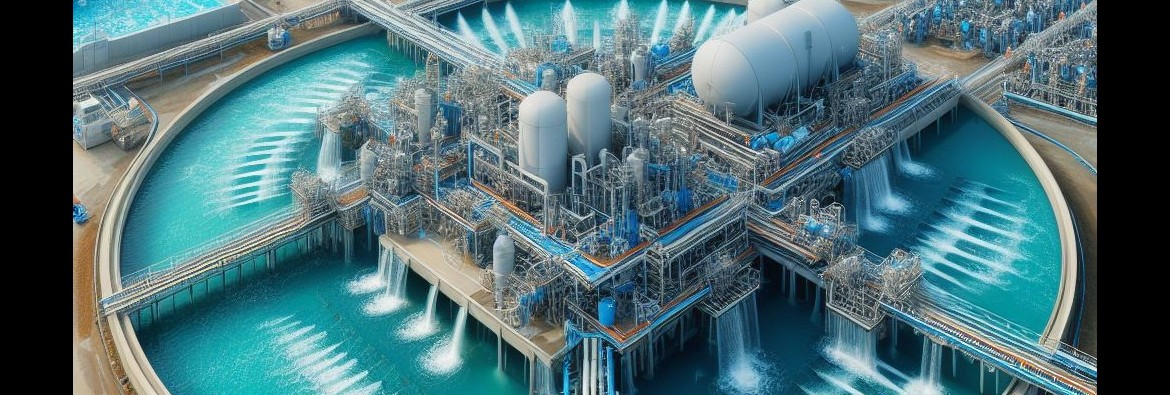

Catalytic ozone oxidation wastewater technology stabilizes and homogenizes the wastewater that needs advanced treatment in the regulating tank.

The effluent enters the sedimentation filter tank, where it is doped with drugs, flocculated, sedimented and filtered, and the pH value is adjusted to

alkaline. In the ozone catalytic oxidation tank, ozone is in the catalyst active center And under the action of alkaline conditions, strong oxidizing

groups hydroxyl radicals will be generated, causing structural changes in the carbon chains of refractory substances and transforming them into

small molecular substances that are easy to biochemically. The effluent will enter the hydrolysis acidification tank for anaerobic and aerobic biochemistry.

During the treatment, some small molecule pollutants are decomposed and removed, and then enter the contact oxidation tank for full aerobics to reduce

the pollutants. After the effluent settles in the secondary sedimentation tank, the clean water undergoes adsorption and filtration, and the product water

enters the storage tank (product tank) , you can meet the reuse or emission standards.

The characteristic of catalytic ozone oxidation wastewater technology is that under the premise of the existence of active centers on the catalyst carrier,

the oxidation and decomposition effect of ozone can be fully exerted. On the one hand, ozone will easily generate hydroxyl radicals in alkaline solutions.

The generated hydroxyl radicals have high electrode potential, stronger oxidation, and high electron affinity. They can quickly and indiscriminately react

with waste water and are difficult to degrade. Organic matter reacts, and as the pH value increases, the speed of ozone decomposition to form hydroxyl

radicals accelerates (the pH value is generally controlled between 8 and 11); on the other hand, and the most important point, is that under the action of

the catalyst active center , the efficiency of ozone in generating hydroxyl radicals has been greatly improved, the probability of hydroxyl radicals coming

into contact with pollutants has also increased a lot, and the utilization rate of ozone is as high as over 97.5%.

It is worth mentioning that the economic benefits of this technology are very obvious. The application of ordinary ozone oxidation technology has many

advantages in sewage treatment, but the high operating costs (mainly power consumption) and high investment costs of the ozone process have always

been a major constraint on the application and promotion of this technology. In contrast, catalytic ozone oxidation wastewater technology has made

breakthrough progress in terms of both investment cost and operating cost. Due to the existence of the catalyst active center, the efficiency of ozone

in generating hydroxyl radicals under alkaline conditions is increased by 2 times, and the efficiency of degrading and decomposing pollutants is also

improved accordingly. Under the premise of the same effect, power consumption is also saved by 30%. .

Since the catalytic oxidation of ozone in this process only plays a role in the specific stage of converting large-molecule refractory substances into

small-molecule biochemical substances, it does not use the ozone oxidation process to directly decompose and reduce pollutants completely.

In this link, it is better than simply using Ozone oxidation saves investment and operating costs by about 20%. Subsequent biochemical processes

(anaerobic/facultative + aerobic) can completely degrade and remove small molecule biochemical pollutants. Taken together, the use of catalytic

ozone oxidation technology can save about 30% in both investment and operating costs compared with the simple ozone oxidation process, and

it can reduce pollutants more thoroughly and has more market promotion value.