The principle of photocatalyst technology and ultraviolet lamp are used in this technology

The working principle of photocatalyst is mainly reflected in the following two aspects:

1: Principle of decomposition of organic pollutants by photocatalyst

Under the irradiation of ultraviolet light, nanoscale TiO2 absorbs light energy and generates electron-hole pairs.

These hole pairs (photocarriers) will quickly migrate to the surface and activate the H2O and O2 attached to the

surface to generate hydroxyl groups (-OH) and reactive oxygen species (-O). These two highly oxidizing substances

will quickly react with bacteria, viruses and large molecular weight hydrocarbons attached to the surface of the

catalyst to generate harmless CO2 and water. This principle of action is now being widely used in the fields of air

purification and water disinfection. The combination of photocatalyst net and ultraviolet lamp can be used in the

purification of fresh air or air conditioning systems, sewage treatment processes, etc. It has the advantages of energy

saving, long-term effect and no secondary pollution.

2: The hydrophilic self-cleaning principle of photocatalyst

As we discussed before, photocatalysts can effectively decompose adhering pollutants under the action of ultraviolet

light, producing a clean surface. The hydroxyl groups (-OH) generated at the same time will combine with H2O in the

air to make the catalyst surface hydrophilic. Since the walls of buildings using this technology are hydrophilic, dust and

other solid attachments on the surface can be easily washed away by rainwater, while keeping the exterior walls of the

building clean. Save a lot of manual cleaning costs. This type of photocatalyst material attached to building walls can

work using the ultraviolet component of sunlight. However, the ultraviolet energy required when it is first excited is relatively

high, so it must be excited with a high-intensity ultraviolet lamp before production.

It can be seen that, as the source of ultraviolet light, ultraviolet lamps are crucial to the application of photocatalyst technology.

Edit this paragraph

Discussion on factors affecting photocatalyst performance and price

1. Types of titanium dioxide crystals

Titanium dioxide has three crystal structures: anatase, rutile, and brookite. The most common ones on the market are anatase and rutile.

Anatase type: a product used in photocatalyst technology, with high hydroxide radical saturation and strong oxidative decomposition ability;

Rutile type: coating grade titanium dioxide, with low hydroxide radical saturation and weak oxidative decomposition ability.

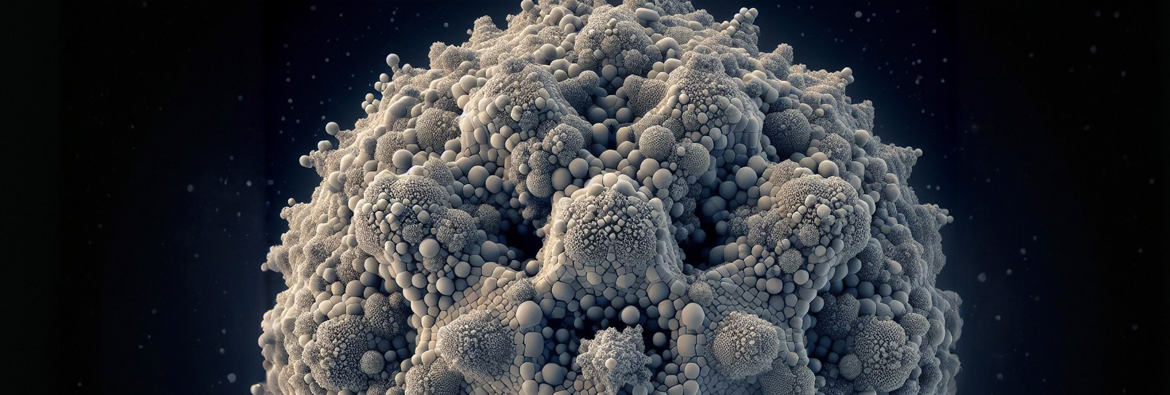

2. Titanium dioxide crystal particle size

The photocatalyst acts on the surface. The larger the surface area, the stronger the processing ability. On the same processing surface,

the smaller the particle size, the larger the relative surface area (the larger the specific surface area), and the stronger the oxidative

decomposition ability. Data shows that particles with a particle size below 7 nanometers have the greatest destructive power against bacteria.

Internationally, materials with particle sizes below 100 nanometers are generally collectively referred to as nanomaterials; different particle

sizes require different production processes. The smaller the particle size, the more complex the process requirements and the higher the

production cost. For example, the price of one ton of titanium dioxide powder of about 100 nanometers is 20,000 to 30,000 yuan. And

every time the particle size decreases by one order of magnitude, the price does not simply double or triple. However, domestic companies

have already achieved the titanium dioxide particle size of photocatalyst spray liquid to 1.0 nanometers.

3. Adhesion technology

One of the key technologies of photocatalyst. One of the key features of photocatalyst technology is long-term effectiveness. If the bonding

technology is not up to standard, the titanium dioxide will easily fall off, making it impossible to have long-term effectiveness, and will have

a negative impact on the vision of the treated surface. For example, when the surface of a car instrument assembly is processed, parts of it

fall off, forming patches. In addition, if the bonding technology is not up to standard, the titanium dioxide will decompose the adhesive,

causing it to fall off.

4. Dispersion Technology

One of the patented technologies of photocatalyst.

Titanium dioxide particles have a characteristic. When present in a liquid, both ends of the particles are acidic and alkaline. If the dispersion

technology is not good, larger individual titanium dioxide particles will be formed, which is contrary to the nanotechnology (large specific

surface area) required by photocatalyst technology. , the processing power drops sharply.

http://www.ozonewish.com#BINGWISH#AFFORDANCEWISH#ozonewish.com#ozonewish#Air purifier#Clean purifierPhotocatalyst#Photocatalytic#Titanium dioxide (TiO2)#Air purification#Volatile Organic Compounds (VOCs)#Catalytic oxidation#Indoor air quality#Odor removal#UV-A light #Catalytic reaction